Vancouver, B.C. April 11, 2022 – Search Minerals Inc. (TSXV: SMY | OTCQB: SHCMF) (“Search” or the “Company”), is pleased to announce updated Mineral Resource Estimates by SLR Consulting (Canada) Ltd. (SLR) for the DEEP FOX and FOXTROT Critical Rare Earth Element (“CREE”) properties in South-East Labrador. The Mineral Resource estimate for DEEP FOX includes results from the recently completed Phase 3 drill program, new metallurgy recovery data, and updated rare earth price forecasts. The updated FOXTROT resource estimate is based on the previous drill programs, new metallurgy recovery data, and updated rare earth price forecasts. The resource estimates for both properties are based on an open pit/underground (OP/UG) mining scenario and will form the basis of the upcoming Preliminary Economic Assessment (“PEA”).

HIGHLIGHTS OF DEEP FOX MINERAL RESOURCE ESTIMATE (OP/UG):

- 3,906,000 tonnes OP Indicated Resource (≥C$260/t NSR cut-off);

- 1,028,000 tonnes OP Inferred Resource (≥C$260/t NSR cut-off);

- 1,148,000 tonnes UG Indicated Resource (≥C$335/t NSR cut-off);

- 2,269,000 tonnes UG Inferred Resource (≥C$ 335/t NSR cut-off);

- Mineralization is open at depth (below 200 m vertical depth) and along strike;

- Phase 4 drill program is required to explore below 200m vertical depth (UG) and to increase indicated resources underground.

HIGHLIGHTS OF FOXTROT MINERAL RESOURCE ESTIMATE (OP/UG):

- 4,577,000 tonnes OP Indicated resource (≥C$260/t NSR cut-off);

- 413,000 tonnes OP Inferred resource (≥C$260/t NSR cut-off);

- 5,462,000 tonnes UG Indicated resource (≥C$335/t NSR cut-off);

- 2,593,000 tonnes UG Inferred resource (≥C$335/t NSR cut-off);

- Mineralization is open at depth – below 450m vertical depth;

- Phase 4 infill drill program is required to increase and improve UG resources.

Greg Andrews, President and CEO of the Company states; “We are very excited to provide the updated and increased Mineral Resource estimates for both DEEPFOX and FOXTROT. The updated Mineral Resource estimate provides the anticipation of an extended project mine life and increased production of rare earth elements for our upcoming PEA report. The recent federal budget has addressed the need for funding and advancement of a Critical Minerals Strategy in Canada and we believe, Search is well poised to benefit from these funding and initiatives. We believe the Company is well positioned to become a crucial player in the creation of a secure North American rare earth element supply chain”

Andrews added: “We are currently completing our 70t bulk sample at SGS Canada and will have approximately 20t of REE concentrate for future processing using our Direct Extraction Technology. Our goal is to produce a neodymium metal bar within a year.”

DEEP FOX RESOURCE ESTIMATE

SLR estimated the DEEP FOX Mineral Resources using drill hole and surface channel data available as of December 31, 2021. Table 1 summarizes the pit constrained and underground constrained Mineral Resource estimates by classification and Table 2 outlines the inputs used to calculate the NSR factors used. Mineral Reserves have not yet been estimated for the project. The primary rare earth elements listed are Praseodymium (Pr), Neodymium (Nd), Terbium (Tb) and Dysprosium (Dy).

| TABLE 1 Estimated Mineral Resources for the DEEP FOX Project as of December 31, 2021 | |||||

| Search Minerals Inc. – DEEP FOX Project | |||||

| Classification | Tonnage | Pr | Nd | Dy | Tb |

| 000s t | ppm | ppm | ppm | ppm | |

| Open Pit | |||||

| Indicated | 3,906 | 399 | 1,482 | 201 | 34 |

| Inferred | 1,028 | 332 | 1,243 | 181 | 30 |

| Underground | |||||

| Indicated | 1,148 | 378 | 1,426 | 203 | 34 |

| Inferred | 2,269 | 382 | 1,443 | 206 | 35 |

| Total Indicated | 5,054 | 394 | 1,469 | 202 | 34 |

| Total Inferred | 3,297 | 366 | 1,381 | 198 | 33 |

Notes:

- CIM definitions were followed for Mineral Resources.

- Open Pit Mineral Resources were reported inside a resource shell at a pit discard NSR cut-off value of C$260/t. Underground Mineral Resources were constrained with mineralization wireframes below the resource shell and validated using underground mining solids based on an NSR cut-off value of C$335/t. Both cut-off values account for all processing, G&A, refining, and transportation charges. Mining costs were assumed at C$6.50/t ore mined and C$5.00/t waste mined for open pit and C$75.00/t for underground

- NSR values were assigned to blocks using metal prices, metallurgical recoveries, payables (as shown in their respective sections of this report) for each individual element.

- A minimum mining width of 2.0 m was used for both open pit and underground.

- Bulk density varies from 2.71 t/m3 to 2.92 t/m3.

- Revenue attributable to Pr, Nd, Dy, and Tb represent approximately 92% of the total revenue.

- The estimate is of Mineral Resources only and because these do not constitute Mineral Reserves, they do not have demonstrated economic viability.

- Totals may not add or multiply accurately due to rounding.

| TABLE 2 Inputs Used to Calculate the NSR Factors | |||||

| Oxide Price | Element to Oxide Conversion Factor | Recoveries | NSR Factor | ||

| Element | (US$/kg) | (%) | (C$/ppm) | ||

| Praseodymium | 108 | 1.17 | 88.6 | 0.137 | |

| Neodymium | 110 | 1.17 | 86.2 | 0.135 | |

| Dysprosium | 614 | 1.15 | 84.0 | 0.703 | |

| Terbium | 1,535 | 1.15 | 84.0 | 1.763 | |

Notes:

- An exchange rate of 1.25 (C$:US$) was used to convert oxide prices.

- Off-site treatment charges of US$5.00/kg for total rare earth oxides (TREO) plus US$20.00/kg for heavy rare earth oxides (HREO) were assumed and are included in the operating costs.

- Recoveries to a mixed REO concentrate are based on test-work and a further recovery loss for separation has been assumed (2% for Neodymium and Praseodymium, and 5% for all HREO).

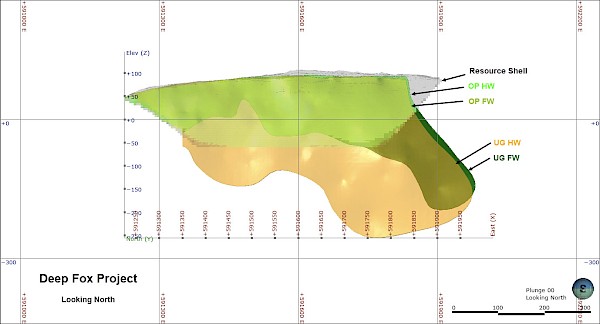

The DEEP FOX Mineral Resource estimation was based on 60 drill holes and 31 surface channels, totalling 2,166.0 m of mineralized core and 573.8 m of mineralized channel samples. The wireframes were modelled in Leapfrog Geo 2021.2.2 software with the interpretation constrained using a minimum NSR value of C$260/t and a minimum mining width of 2.0 m. The DEEP FOX deposit comprises two resource wireframes, Hanging Wall Zone (HW) and Footwall Zone (FW). Narrow intercepts were expanded to achieve a minimum thickness where required, and occasional assays below the minimum NSR modelling value were included to maintain wireframe continuity. Evaluation of raw assay grade values indicated that high-grade values did not require capping. Assays were composited to fixed two-metre-long intervals within resource wireframes, adding intervals shorter than half length to previous composite. (FIGURE 1 – DEEP FOX Resource Wireframes and Resource Shell)

Block modelling and grade estimation were completed using the Leapfrog Geo EDGE module. The grade was estimated using Ordinary Kriging (OK) with variable orientations in a single pass. For the FW and HW zones, blocks were estimated using a maximum of eight samples, a single sample minimum, and a limit of two samples per drill hole. The grades were estimated into a whole block model with 5 metre x 2.5 metre x 5 metre block size, using majority rules for resource domain flagging. Resources were reported inside an optimized pit resource shell generated with Whittle software. Mineral Resource classification is based on the sample spacing as well as the level of confidence of the “qualified person” (as such term is defined in National Instrument 43-101 – Standards of Disclosure for Mineral Projects (“NI 43-101”)) in the geological knowledge and input information.

FIGURE 1 DEEP FOX Resource Wireframes and Resource Shell

FOXTROT RESOURCE ESTIMATE

SLR estimated the FOXTROT Mineral Resources using drill hole and surface channel data available as of December 31, 2021. Table 3 summarizes the pit constrained and underground constrained Mineral Resource estimates by classification and Table 2 outlines the inputs used to calculate the NSR factors used. Mineral Reserves have not yet been estimated at the project. The primary rare earth elements listed are Praseodymium (Pr), Neodymium (Nd), Terbium (Tb) and Dysprosium (Dy).

| TABLE 3 Estimated Mineral Resources for the FOXTROT Project as of December 31, 2021 | |||||

| Search Minerals Inc. – FOXTROT Project | |||||

| Classification | Tonnage | Pr | Nd | Dy | Tb |

| 000s | ppm | ppm | ppm | ppm | |

| Open Pit | |||||

| Indicated | 4,577 | 366 | 1,372 | 175 | 30 |

| Inferred | 413 | 322 | 1,202 | 173 | 29 |

| Underground | |||||

| Indicated | 5,462 | 365 | 1,366 | 177 | 30 |

| Inferred | 2,593 | 379 | 1,413 | 177 | 31 |

| Total Indicated | 10,040 | 366 | 1,368 | 176 | 30 |

| Total Inferred | 3,006 | 371 | 1,384 | 177 | 30 |

Notes:

- CIM definitions were followed for Mineral Resources.

- Open Pit Mineral Resources were reported inside a resource shell at pit discard NSR cut-off value of C$260/t. Underground Mineral Resources were constrained with mineralization wireframes below the resource shell and validated using underground mining solids based on an NSR cut-off value of C$335/t. Both cut-off values account for all processing, G&A, refining, and transportation charges. Mining costs were assumed at C$6.50/t ore mined and C$5.00/t waste mined for open pit and C$75.00/t for underground

- NSR values were assigned to blocks using metal prices, metallurgical recoveries, payables (as shown in their respective sections of this report) for each individual element.

- A minimum mining width of 2.0 m was used for both open pit and underground.

- Bulk density varies from 2.71 t/m3 to 2.92 t/m3.

- Revenue attributable to Pr, Nd, Dy, and Tb represent approximately 92% of the total revenue.

- The estimate is of Mineral Resources only and because these do not constitute Mineral Reserves, they do not have demonstrated economic viability.

- Totals may not add or multiply accurately due to rounding.

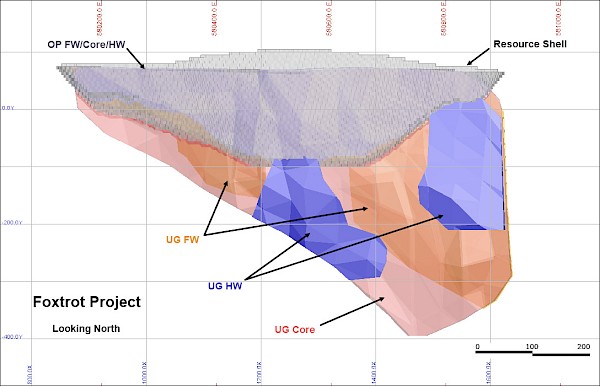

The FOXTROT Mineral Resource estimation was based on 57 drill holes and 18 surface channels, totalling 1,675.6 m of mineralized core and 274.4 m of mineralized channel sampling. The wireframes were modelled in GEMS 6.8.1 software with the interpretation constrained using a minimum NSR value of C$260/t and a minimum mining width of 2.0 m. The FOXTROT deposit comprises three resource wireframes: Hanging Wall Zone (HW), Footwall Zone (FW), and Core Zone (C). Narrow intercepts were expanded to achieve a minimum thickness where required, and occasional assays below the minimum NSR modelling value were included to maintain wireframe continuity. Evaluation of raw assay grade values indicated that high-grade values did not require capping. Assays were composited to fixed two-metre-long intervals within resource wireframes, discarding composites shorter then 0.5 m. (FIGURE 2 – Foxtrot Resource Wireframes and Resource Shell)

Block modelling and grade estimation were completed using Geovia Gems 6.8.3. The grade was estimated using Ordinary Kriging (OK) in two passes. Block grades were estimated using a maximum of five samples, minimum a single sample, and a limit of two samples per drill hole in the first pass, and maximum of six samples, minimum a single sample, and no restriction per drill hole in the second pass. The grades were estimated into a percent block model with 5 metre x 2.5 metre x 5 metre block-size. Resources were reported inside an optimized pit resource shell generated with Whittle software. Mineral Resource classification is based on the sample spacing. Mineral Resource classification is based on the sample spacing as well as the Qualified Person's level of confidence in the geological knowledge and input information.

FIGURE 2 Foxtrot Resource Wireframes and Resource Shell

DEEP FOX AND FOXTROT DEPOSITS

The DEEP FOX Mineral Resource, including Phase 1 to Phase 3 drill data, has increased by approximately 25% from the 2019 estimate that was based on the Phase 1 and Phase 2 drill programs (see Technical Report of the Deep Fox Project, Newfoundland and Labrador, Canada.NI 43-101 Report

Katherine M. Masun November 12, 2019)). A phase 4 drill program at DEEP FOX anticipates exploring for mineralization below the 200m level (underground) and upgrading inferred underground resources to indicated resources.

The FOXTROT Mineral Resource, including Phase 1 to Phase 3 drill data, has increased by approximately 60% from the 2016 estimate using updated metallurgical recoveries and rare earth prices (see Technical Report of the Foxtrot Project, Newfoundland and Labrador, Canada.NI 43-101 Report Katherine M. Masun Ian C. Weir John R. Goode April 28, 2016). The mineralization is open below 450m depth. A phase 4 drill program at FOXTROT would explore for additional mineralization below the 450m level (underground) and help to upgrade inferred underground resources to indicated resources.

The DEEP FOX (formerly Deepwater Fox) property (see Search Minerals news releases Jan. 27th 2015 and Oct. 15th 2015) occurs about 2 km NE from the port of St. Lewis on the SE Labrador coast and within 12 km of the FOXTROT Deposit (10 km west of St. Lewis). Both resources can be accessed by all-weather gravel and paved roads and by water through the port of St. Lewis.

| TABLE 4 Estimated Mineral Resources for the FOXTROT and DEEP FOX Projects as of December 31, 2021 | |||||

| Search Minerals Inc. – FOXTROT and DEEP FOX Projects | |||||

| Classification | Tonnage | Pr | Nd | Dy | Tb |

| 000s | ppm | ppm | ppm | ppm | |

| Open Pit | |||||

| Indicated | 8,483 | 381 | 1,422 | 187 | 32 |

| Inferred | 1,441 | 329 | 1,231 | 179 | 30 |

| Underground | |||||

| Indicated | 6,611 | 368 | 1,376 | 182 | 31 |

| Inferred | 4,862 | 380 | 1,427 | 191 | 33 |

| Total Indicated | 15,094 | 375 | 1,402 | 185 | 32 |

| Total Inferred | 6,303 | 369 | 1,382 | 188 | 32 |

Notes:

- CIM definitions were followed for Mineral Resources.

- Open Pit Mineral Resources were reported inside a resource shell at pit discard NSR cut-off value of C$260/t. Underground Mineral Resources were constrained with mineralization wireframes below the resource shell and validated using underground mining solids based on an NSR cut-off value of C$335/t. Both cut-off values account for all processing, G&A, refining, and transportation charges. Mining costs were assumed at C$6.50/t ore mined and C$5.00/t waste mined for open pit and C$75.00/t for underground

- NSR values were assigned to blocks using metal prices, metallurgical recoveries, payables (as shown in their respective sections of this report) for each individual element.

- A minimum mining width of 2.0 m was used for both open pit and underground.

- Bulk density varies from 2.71 t/m3 to 2.92 t/m3.

- Revenue attributable to Pr, Nd, Dy, and Tb represent approximately 92% of the total revenue.

- The estimate is of Mineral Resources only and because these do not constitute Mineral Reserves, they do not have demonstrated economic viability.

- Totals may not add or multiply accurately due to rounding.

Qualified Persons:

Katharine M. Masun, P.Geo. Consultant Geologist, SLR Consulting (Canada), Qualified Person (as defined by NI 43-101), and Tudorel Ciuculescu, P.Geo., Consultant Geologist, SLR Consulting (Canada), Qualified Person (as defined by NI 43-101) have prepared and take responsibility for the Deep Fox and Foxtrot Mineral Resource estimates.

Randy Miller, Ph.D., P.Geo, is the Company's Vice President, Exploration, and is a “qualified person” (as defined by NI 43-101) and has supervised the preparation of and approved all scientific and technical information herein and has conducted appropriate verification on the underlying data. The Company will endeavor to meet high standards of integrity, transparency, and consistency in reporting technical content, including geological and assay (e.g., REE) data.

About Search Minerals Inc.

Led by a proven management team and board of directors, Search is focused on finding and developing Critical Rare Earths Elements (CREE), Zirconium (Zr) and Hafnium (Hf) resources within the emerging Port Hope Simpson – St. Lewis CREE District of South East Labrador. The Company controls a belt 63 km long and 2 km wide and is road accessible, on tidewater, and located within 3 local communities. Search has completed a preliminary economic assessment report for FOXTROT, and a resource estimate for DEEP FOX. Search is also working on three exploration prospects along the belt which include: FOX MEADOW, SILVER FOX and AWESOME FOX.

Search has continued to optimize our patented Direct Extraction Process technology with the support from the Department of Industry, Energy and Technology, Government of Newfoundland and Labrador, and from the Atlantic Canada Opportunity Agency. We have completed two pilot plant operations and produced highly purified mixed rare earth carbonate concentrate and mixed REO concentrate for separation and refining. We also recognize the continued support by the Government of Newfoundland and Labrador for its Junior Exploration Program.

Search Minerals was selected to participate in the Government of Canada Accelerated Growth Service (“AGS”) initiative, which supports high growth companies. AGS, as a 'one-stop shop' model, provides Search with coordinated access to Government of Canada resources as Search continues to move quickly to production and contribute to the establishment of a stable and secure rare earth element North American and European supply chain.

For further information, please contact:

Greg Andrews

President and CEO

Tel: 604-998-3432

E-mail: info@searchminerals.ca

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Cautionary Statement Regarding “Forward-Looking” Statements:

This news release contains "forward-looking information "and "forward looking statements" within the meaning of applicable Canadian securities laws. Such forward-looking statements include, without limitation: statements with respect to Mineral Resource estimates; anticipated advancement of the Company's exploration, production and processing plans; and the preparation and timing of the PEA report. These statements are based on information currently available to the Company and the Company provides no assurance that actual results will meet management's expectations. In certain cases, forward-looking information may be identified by such terms as "anticipates", "believes", "could", "estimates", "expects", "may", "shall", "will", or "would".

Forward-looking information contained in this news release is based on certain factors and assumptions regarding, among other things, the estimation of Mineral Resources, the realization of resource estimates, change in market prices, the availability of necessary financing, the timing and amount of future exploration and development expenditures, the, the progress of exploration and development activities, the receipt of necessary regulatory approvals, and assumptions with respect to environmental risks, title disputes or claims, and other similar matters. While the Company considers these assumptions to be reasonable based on information currently available to it, they may prove to be incorrect.

Although the Company believes the expectations expressed in such forward-looking statements are based on reasonable assumptions, such statements are not guarantees of future performance and actual results or developments may differ materially from those in the forward-looking statements. Factors that could cause actual results to differ materially from those in forward-looking statements include: changes in market conditions, unsuccessful exploration results, unanticipated costs and expenses, inaccurate resource estimates, changes in the price of minerals, unanticipated changes in key management personnel and general economic conditions. In addition, mining exploration and development is an inherently risky business. Accordingly, actual events may differ materially from those projected in the forward-looking statements. This list is not exhaustive of the factors that may affect any of the Company's forward-looking statements. Reference should be made to the Company's public filings available under its profile on www.sedar.com for further risk factors.

These and other factors should be considered carefully and readers should not place undue reliance on the Company's forward-looking statements. The Company does not undertake to update any forward-looking statement that may be made from time to time by the Company or on its behalf, except in accordance with applicable securities laws.